USB cables are an indispensable part of modern life, powering our devices and keeping us connected. Yet, they are often the first accessory to fail due to everyday wear and tear. For power bank manufacturers, providing long-lasting, durable USB cables can set your brand apart and enhance customer satisfaction. In this guide, I’ll share actionable tips to make USB cables last a lifetime, helping you build quality and reliability into your products.

To make a USB cable last a lifetime, focus on careful usage and quality materials. Avoid bending or yanking the cable, store it in a protective case, and reinforce weak points with cable protectors. High-quality manufacturing, including durable insulation and robust connectors, ensures cables withstand frequent use without degrading.

1. Choose High-Quality Materials for USB Cables

Durability starts with material selection. When manufacturing USB cables, consider materials that resist daily wear and tear:

- TPE or Braided Nylon: These materials are flexible yet robust, reducing the risk of fraying.

- Metal Connectors: Opt for sturdy metal connectors with reinforced stress relief points.

- Double Insulation: Multi-layered insulation can shield internal wires from damage caused by bending or external pressure.

By prioritizing these materials, you create cables that stand up to heavy usage, enhancing customer trust in your brand.

2. Reinforce Weak Points

The most common failure points in USB cables are the ends, where cables connect to the port. Reinforcing these areas is crucial:

- Add strain relief sleeves to minimize stress on the cable ends.

- Use spring guards or coiled reinforcements to reduce bending damage.

- Consider innovative designs, such as angled connectors, which are less prone to stress.

Reinforcements not only improve longevity but also communicate a commitment to quality.

3. Encourage Proper User Habits

Providing usage tips to your customers can significantly extend the life of their USB cables. Include these recommendations in your product packaging or user manuals:

- Unplug Carefully: Teach users to pull from the connector, not the cable, to avoid straining the internal wires.

- Avoid Bending: Sharp bends weaken the copper conductors inside the cable.

- Proper Storage: Encourage storing cables in protective cases to prevent tangling or fraying.

These small habits make a big difference, especially for power bank users who rely on portable charging.

4. Incorporate Moisture Resistance

USB cables are frequently exposed to diverse environments, from coffee spills to outdoor humidity. Moisture can corrode connectors and damage internal wiring, leading to failure. Manufacturers can prevent this by:

- Using waterproof designs for USB cables.

- Applying sealed connectors to protect the cable internals.

- Adding a moisture-resistant coating on the insulation.

For outdoor or travel-friendly power banks, these features add tremendous value.

5. Test for Longevity

Rigorous testing during the production phase ensures your USB cables meet durability expectations. Implement tests like:

- Bend Tests: Evaluate how many bends the cable can endure without failing. Aim for at least 10,000 cycles.

- Pull Tests: Check the cable’s resistance to pulling and tugging.

- Load Testing: Ensure the cable can handle heavy data and power loads without overheating or losing efficiency.

By meeting these standards, you assure customers of a high-quality product.

6. Emphasize Compatibility with Fast Charging

Modern users demand more from their USB cables. For power bank manufacturers, compatibility with fast-charging protocols like Qualcomm Quick Charge or USB Power Delivery is a must. Ensure your cables:

- Support fast charging and data transfer.

- Are compatible with high-demand devices like smartphones, tablets, and laptops.

- Have certifications to back these capabilities.

Fast-charging support ensures your cables remain relevant in a competitive market.

7. Include Cable Protectors and Accessories

Small add-ons can make a big difference. Consider including accessories like:

- Cable protectors: To reduce wear on high-stress areas.

- Organizing ties: To prevent tangling during storage.

- Carrying pouches: For travel-ready convenience.

These extras enhance user experience and position your power bank as a premium product.

8. Highlight Certifications for Quality Assurance

Customers value products with recognized certifications that guarantee safety and performance. Ensure your USB cables are:

- USB-IF Certified: Signifying adherence to industry standards.

- Tested for electromagnetic compatibility to ensure safe operation.

Highlighting these certifications in your marketing assures customers they are investing in reliable and safe products.

9. Why Choose Our Customizable USB Cables?

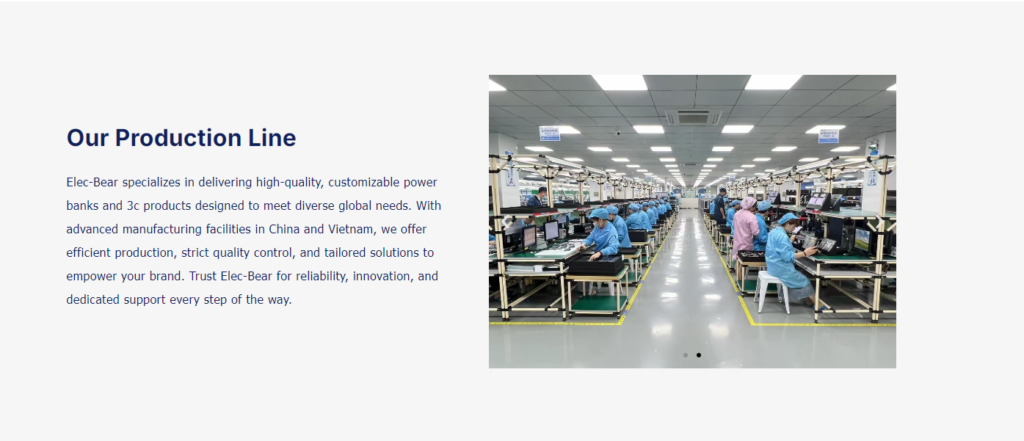

As a trusted supplier of customizable 3C electronic products, we specialize in creating USB cables designed for durability and performance, tailored to the unique needs of power bank manufacturers. Here’s why our cables are the perfect fit for your brand:

1. Built for Longevity

Our cables are engineered with premium materials like braided nylon and TPE, ensuring flexibility and resistance to wear and tear. With reinforced connectors and strain relief designs, our cables withstand the rigors of daily use, including heavy-duty applications.

2. Customization to Match Your Brand

We offer comprehensive customization options, allowing you to design USB cables that align with your brand’s identity:

- Choose from a variety of materials, colors, and lengths.

- Add your logo or unique branding to connectors and packaging.

- Customize functionality, such as fast-charging support or waterproof designs.

3. Certified for Performance

Our cables are USB-IF certified, ensuring they meet industry standards for safety, durability, and compatibility. Whether your power banks require USB-C, Micro-USB, or Lightning connectors, our products are rigorously tested to guarantee superior performance.

4. Bulk Solutions with Competitive Pricing

As a manufacturer, we understand the importance of cost-efficiency. That’s why we offer bulk production solutions at competitive pricing, helping you maintain profitability without compromising quality.

5. Dedicated After-Sales Support

Our commitment to quality extends beyond manufacturing. We provide excellent after-sales support, ensuring any concerns are promptly addressed and resolved.

Ready to Elevate Your Power Bank Brand?

Partnering with us ensures your customers receive USB cables that enhance their experience and solidify your brand’s reputation for quality. Let’s discuss how we can customize USB cables tailored to your needs. Contact us today to learn more or request a sample!